Ever felt your car was just...off? Like it wasn't quite delivering the power it used to, or maybe the fuel economy took a sudden nosedive? There are a multitude of reasons why your trusty vehicle might be acting up, but one often-overlooked culprit could be a faulty knock sensor.

Dealing with diminished engine power, unexplained drops in fuel efficiency, and that nagging "check engine" light can be incredibly frustrating. You might be throwing money at the gas pump more often, and the joy of driving might slowly be replaced by a feeling of unease. Identifying the root cause can feel like searching for a needle in a haystack, and the potential for further engine damage only adds to the worry.

This blog post dives deep into the world of knock sensors. We'll explore what they do, the telltale signs of a failing sensor, how it impacts your car's performance, and what you can do to address the issue. Consider this your comprehensive guide to understanding and tackling knock sensor problems.

In essence, we'll cover the symptoms indicating a potential knock sensor issue, the negative effects on your vehicle's performance and fuel economy, and the steps you can take to diagnose and fix the problem. By understanding the role of the knock sensor and its potential failures, you can better protect your engine and ensure a smoother, more efficient driving experience. Key terms we'll be exploring include: knock sensor, engine knock, pre-ignition, timing retard, fuel efficiency, and OBDII codes.

My Personal Experience with a Faulty Knock Sensor

I remember one sweltering summer day, driving my old pickup truck through the desert. The engine started making this weird, almost metallic pinging sound, especially when going uphill. I initially dismissed it as "old truck noises," but then the 'check engine' light illuminated, mocking my complacency. A sinking feeling washed over me. After limping home, I hooked up an OBDII scanner and pulled a code pointing to – you guessed it – a faulty knock sensor. I was a novice then. This was a rude awakening to the delicate dance happening under my hood. It wasn't just an annoying noise; it was my engine begging for help!

The experience taught me the importance of paying attention to subtle changes in my vehicle's behavior. The knock sensor is a crucial component in modern engines, constantly listening for abnormal combustion patterns. When it detects knock (also known as pre-ignition or detonation), it signals the engine control unit (ECU) to retard the ignition timing, preventing potentially catastrophic engine damage. Ignoring the early warning signs, like I did, could have led to expensive repairs. Since that day, I always listen carefully for unusual engine sounds and proactively check any warning lights. Learning to diagnose a faulty knock sensor saved me a lot of money, prevented more serious issues, and gave me confidence to solve future car problems. A malfunctioning knock sensor can significantly impact engine timing and efficiency, potentially leading to long-term engine damage. This experience was my first lesson on how important this little device is.

What Exactly is a Knock Sensor?

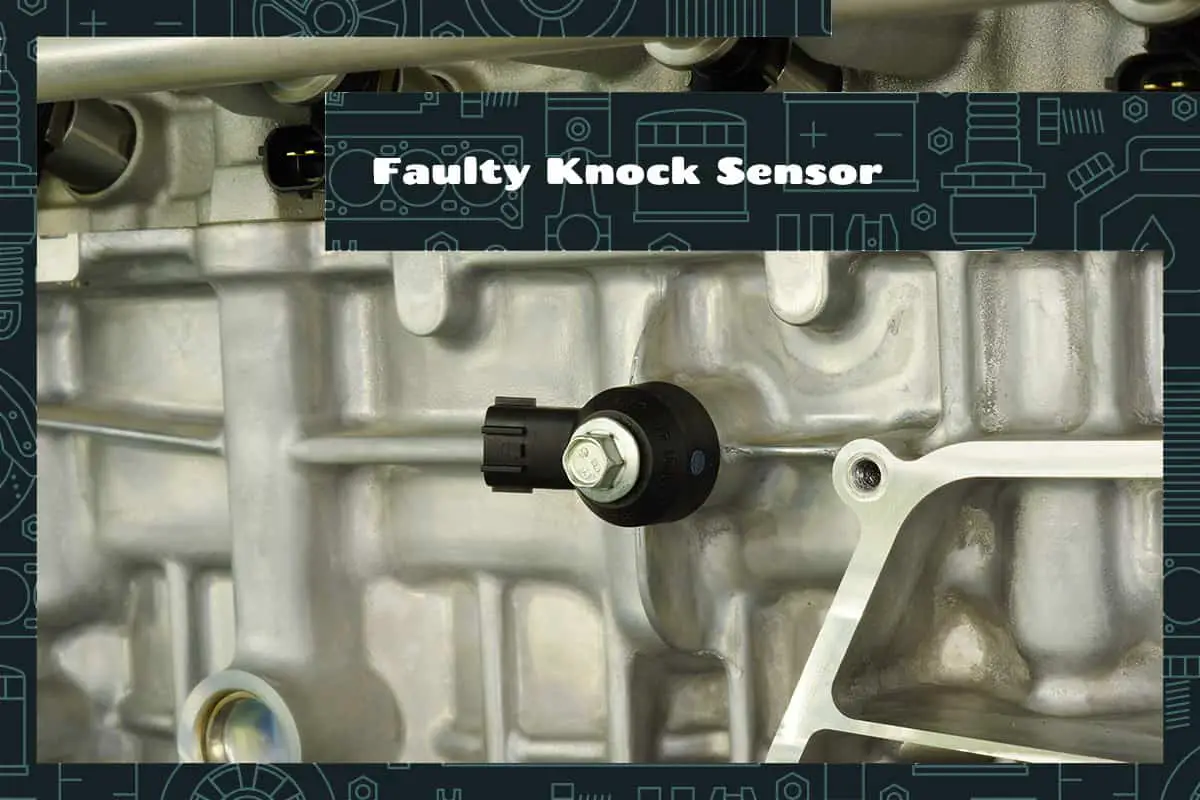

The knock sensor, at its core, is a tiny microphone for your engine. It's usually mounted on the engine block or cylinder head and its primary job is to listen for vibrations caused by engine knock, or detonation. Engine knock occurs when the air-fuel mixture in the cylinder ignites unevenly or too early, creating a rapid pressure spike that sounds like a metallic pinging or knocking. This uncontrolled combustion can severely damage engine components like pistons, connecting rods, and cylinder heads.

The knock sensor is typically a piezoelectric device. This means it generates an electrical signal when subjected to mechanical stress or vibration. When the sensor detects the vibrations associated with engine knock, it sends a signal to the engine control unit (ECU). The ECU then responds by retarding the ignition timing. Retarding the timing means delaying when the spark plug fires, giving the air-fuel mixture more time to burn evenly and preventing knock. In some cases, the ECU might also adjust the fuel mixture to help control combustion. Without a functioning knock sensor, the engine is vulnerable to the damaging effects of detonation, especially under high load or during acceleration. It is important to get your knock sensor checked if you have a feeling that you might have a faulty knock sensor. The longer you wait the more costly it will become.

The History and Myths Surrounding Knock Sensors

The concept of knock control dates back to the early days of internal combustion engines, but the modern knock sensor as we know it began to emerge in the 1970s, driven by stricter emissions regulations and the need for more efficient engines. Early knock control systems were relatively simple, but as engine technology advanced, so did the sophistication of knock sensors and their integration with engine management systems. The need to run higher compression engines on lower octane fuel also contributed to the use of knock sensors.

One common myth is that knock sensors are only necessary for high-performance engines. While it's true that high-performance engines are more susceptible to knock due to their higher compression ratios, all modern gasoline engines benefit from knock control. Another myth is that using higher octane fuel eliminates the need for a functioning knock sensor. While higher octane fuel can reduce the likelihood of knock, it doesn't guarantee complete immunity. A faulty knock sensor can still lead to performance issues and potential engine damage, even with premium fuel. Modern vehicles have many sensors under the hood.

Knock sensors have been used since the 70's and used to prevent damage and to increase the engine longevity.

Unlocking the Hidden Secrets of the Knock Sensor

The knock sensor's hidden secret lies in its ability to constantly adapt to changing conditions. It's not just a simple on/off switch; it provides continuous feedback to the ECU, allowing the engine to operate at its optimal performance level while maintaining a safe margin against knock. The knock sensor works in tandem with other engine sensors, such as the oxygen sensor, mass airflow sensor, and throttle position sensor, to create a comprehensive picture of the engine's operating conditions.

Another secret is its resilience. While knock sensors are robust, they are constantly exposed to heat, vibration, and potentially corrosive fluids. Over time, this harsh environment can lead to sensor failure. That is why it is important to check the sensors when the check engine light appears on the dash. Regular inspection of the wiring harness connected to the knock sensor is also crucial. Damaged or corroded wiring can disrupt the signal transmission to the ECU, leading to false readings or complete sensor failure. Understanding these hidden aspects of the knock sensor allows for more effective troubleshooting and maintenance, ensuring optimal engine performance and longevity.

Recommendations for Dealing with a Faulty Knock Sensor

If you suspect a faulty knock sensor, the first step is to get a proper diagnosis. Use an OBDII scanner to check for any stored trouble codes. Common codes associated with knock sensor issues include P0325 (Knock Sensor 1 Circuit Malfunction) and P0330 (Knock Sensor 2 Circuit Malfunction). However, it's important to remember that these codes could also indicate other problems, such as wiring issues or a faulty ECU. Therefore, further investigation is often necessary.

Visually inspect the knock sensor and its wiring harness for any signs of damage, such as cracks, corrosion, or loose connections. If possible, use a multimeter to check the sensor's resistance and voltage output. Compare the readings to the manufacturer's specifications to determine if the sensor is functioning correctly. If the sensor is indeed faulty, replace it with a new, high-quality sensor from a reputable brand. Always follow the manufacturer's instructions for installation, and be sure to torque the sensor to the correct specification to ensure proper operation. Regular maintenance, including periodic inspections of the knock sensor and its wiring, can help prevent future problems.

Understanding OBDII Codes Related to Knock Sensors

OBDII (On-Board Diagnostics II) codes are standardized codes used to identify specific problems within a vehicle's engine and related systems. When a fault is detected, the ECU (Engine Control Unit) stores a corresponding code and illuminates the "check engine" light on the dashboard. For knock sensors, there are several common OBDII codes that might appear, each indicating a specific issue.

As mentioned earlier, P0325 and P0330 are two of the most frequent codes. P0325 typically indicates a malfunction in the knock sensor 1 circuit, while P0330 points to a problem with the knock sensor 2 circuit (if your vehicle has two knock sensors). Other related codes might include P0324 (Knock Control System Malfunction) or codes that specify a specific type of fault, such as "Knock Sensor Circuit Low Input" or "Knock Sensor Circuit High Input." When you retrieve an OBDII code related to the knock sensor, it's crucial to understand that it's only a starting point for diagnosis. It doesn't necessarily mean that the knock sensor itself is faulty. The code could be triggered by a wiring problem, a loose connection, or even a faulty ECU. Therefore, further testing and inspection are essential to pinpoint the root cause of the issue.

Tips for Maintaining Your Knock Sensor

Maintaining your knock sensor can significantly prolong its lifespan and ensure optimal engine performance. One of the most important tips is to protect the sensor from excessive heat and vibration. Avoid aggressive driving habits, such as frequent hard accelerations or high-speed cruising, which can put undue stress on the engine and increase the likelihood of knock. Also, make sure your cooling system is functioning properly to prevent overheating, as excessive heat can damage the knock sensor.

Another important tip is to keep the engine bay clean. Dirt, grime, and oil buildup can insulate the knock sensor, preventing it from accurately detecting engine knock. Periodically clean the engine bay with a mild degreaser and a soft brush to remove any accumulated debris. When working on the engine, be careful not to damage the knock sensor or its wiring harness. Avoid using excessive force when tightening bolts or disconnecting connectors near the sensor. If you're replacing other engine components, such as spark plugs or fuel injectors, make sure to follow the manufacturer's instructions carefully to avoid introducing any new problems that could trigger knock. A little bit of care can go a long way in keeping your knock sensor healthy and your engine running smoothly.

The Role of Fuel Octane in Relation to Knock Sensors

Fuel octane rating is a measure of a fuel's resistance to knock or detonation. Higher octane fuels are more resistant to pre-ignition and are typically recommended for high-performance engines with higher compression ratios. The relationship between fuel octane and knock sensors is that the knock sensor acts as a safeguard against using fuel with an insufficient octane rating.

When you use fuel with a lower octane rating than recommended for your engine, the risk of knock increases. If the knock sensor detects knock, it signals the ECU to retard the ignition timing, which reduces the likelihood of further knock. However, retarding the timing also reduces engine power and fuel efficiency. Therefore, it's always best to use the fuel octane rating recommended by the manufacturer. While using higher octane fuel than recommended won't necessarily harm your engine, it's usually a waste of money, as it won't provide any noticeable performance benefits unless your engine is specifically designed to take advantage of it. The knock sensor plays a critical role in protecting the engine regardless of the fuel you use.

Fun Facts About Knock Sensors

Did you know that some modern engines use multiple knock sensors to more accurately pinpoint the location of knock within the engine? This allows the ECU to make more precise adjustments to the ignition timing and fuel mixture, optimizing performance and fuel efficiency. Also, knock sensors aren't just used in gasoline engines; they can also be found in diesel engines to detect abnormal combustion.

Another interesting fact is that the sensitivity of knock sensors can be affected by factors such as engine temperature, sensor mounting location, and even the type of engine oil used. That's why it's important to follow the manufacturer's recommendations for maintenance and fluid changes. And here's a quirky one: some early knock sensors were actually based on technology borrowed from hearing aids! The principle of using a piezoelectric element to detect vibrations was the same, but the application was obviously quite different. Knock sensors are really a testament to how sophisticated and complex modern engines have become.

How to Diagnose a Faulty Knock Sensor

Diagnosing a faulty knock sensor requires a systematic approach, combining visual inspection, OBDII code analysis, and electrical testing. Start by visually inspecting the knock sensor and its wiring harness for any signs of damage, such as cracks, corrosion, or loose connections. Pay close attention to the connector and the wiring insulation, as these are common areas for problems. Next, use an OBDII scanner to retrieve any stored trouble codes. Note down the codes and research their meaning to understand the potential issues.

If you have access to a multimeter, you can perform some basic electrical tests on the knock sensor. Check the sensor's resistance and voltage output, comparing the readings to the manufacturer's specifications. A significant deviation from the specified values could indicate a faulty sensor. You can also perform a "tap test" by gently tapping on the engine block near the knock sensor while monitoring the sensor's output signal. A functioning sensor should produce a small voltage spike when tapped. If the sensor fails these tests, it's likely faulty and needs to be replaced. Remember to consult your vehicle's service manual for specific testing procedures and specifications.

What if You Ignore a Faulty Knock Sensor?

Ignoring a faulty knock sensor can have serious consequences for your engine. Without a functioning knock sensor, the ECU is unable to detect and respond to engine knock, leaving your engine vulnerable to the damaging effects of uncontrolled combustion. Over time, this can lead to severe engine damage, including piston damage, connecting rod failure, and cylinder head damage.

Even if the engine doesn't suffer immediate catastrophic damage, a faulty knock sensor can still lead to significant performance issues. The ECU might excessively retard the ignition timing, resulting in reduced power, poor fuel efficiency, and rough running. In some cases, the ECU might even enter a "limp mode," severely limiting engine power to prevent further damage. The cost of repairing or replacing a damaged engine far outweighs the cost of replacing a faulty knock sensor. Ignoring the warning signs and delaying repairs can ultimately lead to a much more expensive and time-consuming repair bill. Be aware of what is going on with your vehicle, and listen to it. The knock sensor is there for a reason.

Listicle: Top 5 Signs of a Faulty Knock Sensor

Here's a quick list of the top 5 signs that might indicate a problem with your knock sensor:

1.Check Engine Light: This is often the first and most obvious sign. The check engine light will illuminate, and an OBDII scanner will likely reveal a code related to the knock sensor.

2.Reduced Engine Power: The engine might feel sluggish or unresponsive, especially during acceleration or when climbing hills.

3.Poor Fuel Efficiency: You might notice a decrease in your gas mileage, even if your driving habits haven't changed.

4.Engine Knocking or Pinging: You might hear a metallic knocking or pinging sound coming from the engine, especially under load.

5.Rough Idling: The engine might idle roughly or unevenly, and you might experience vibrations in the cabin.

If you experience any of these symptoms, it's crucial to have your vehicle inspected by a qualified mechanic to diagnose the problem and take appropriate action. Early detection and repair can prevent more serious engine damage. If you ignore these warning signs you will have to do more work to fix the problem.

Question and Answer Section

Here are some common questions related to faulty knock sensors, answered for your convenience:

Q: Can I drive my car with a faulty knock sensor?

A: While it's technically possible to drive with a faulty knock sensor, it's not recommended. The ECU might retard the timing excessively, leading to reduced power and fuel efficiency. More importantly, you risk damaging your engine if knock occurs without being detected.

Q: How much does it cost to replace a knock sensor?

A: The cost to replace a knock sensor can vary depending on the vehicle make and model, as well as the location of the sensor. Generally, you can expect to pay between $100 and $300, including parts and labor.

Q: Can a bad knock sensor affect my emissions?

A: Yes, a bad knock sensor can affect your emissions. The ECU might compensate for the faulty sensor by adjusting the fuel mixture, which can lead to increased emissions.

Q: Are there any aftermarket performance knock sensors?

A: Yes, there are aftermarket performance knock sensors available. However, it's important to choose a high-quality sensor from a reputable brand to ensure accurate readings and reliable performance.

Conclusion of Faulty Knock Sensor: Symptoms and Impact on Performance

Understanding the role of the knock sensor, recognizing the symptoms of a failing sensor, and taking prompt action are essential for maintaining your engine's health and performance. From recognizing the subtle pinging sounds to interpreting those cryptic OBDII codes, being proactive can save you from costly repairs down the road. Remember, a healthy knock sensor translates to a healthy engine, better fuel efficiency, and a smoother, more enjoyable driving experience. So, listen to your engine, pay attention to the warning signs, and don't hesitate to seek professional help when needed. Your car will thank you for it!