That high-pitched squealing under your hood isn't a friendly greeting – it's likely a cry for help from your serpentine belt! Ignoring it could leave you stranded on the side of the road. Don't let a small problem turn into a major headache.

The sinking feeling when your car makes a strange noise is something every driver dreads. You worry about expensive repairs, unexpected breakdowns, and the inconvenience of being without your vehicle. Is it safe to drive? How much is this going to cost? These questions swirl in your head as you try to decipher the warning signs your car is giving you.

This blog post will guide you through the symptoms of a bad or loose serpentine belt, helping you diagnose the problem early and understand the replacement process. We’ll cover the warning signs, potential causes, and what to do to get your car back on the road safely. Think of it as your go-to guide for serpentine belt troubles!

We've explored the telltale signs of a failing serpentine belt – the squealing, the power steering issues, and the battery problems. You now understand the potential causes, from wear and tear to pulley misalignment. By being proactive and addressing these symptoms early, you can avoid more significant damage and ensure your vehicle's reliability. Remember, a healthy serpentine belt is crucial for a smoothly running engine and a safe driving experience. Knowing when to replace it saves you time, money, and stress in the long run. A regular maintenance check goes a long way, too!

My Serpentine Belt Saga: A Personal Anecdote

Let me tell you a story. It was a cold winter morning, and I was running late for a crucial meeting. As I pulled out of my driveway, a piercing squeal erupted from under the hood. I initially dismissed it, thinking it might just be the cold. But the noise persisted, growing louder with each turn of the steering wheel. My power steering felt heavy, and the dashboard warning lights flickered ominously. Panic started to set in – I knew something was seriously wrong. After managing to limp my car to a nearby mechanic, the diagnosis was clear: a cracked and severely worn serpentine belt. The mechanic explained that the belt was responsible for powering crucial components like the alternator, power steering pump, and air conditioning compressor. Its failure had put me in a potentially dangerous situation. This incident was a wake-up call. I learned firsthand the importance of regular car maintenance and recognizing the warning signs of a failing serpentine belt. Now, I make it a point to inspect my serpentine belt regularly and address any issues promptly. A simple visual check and paying attention to unusual noises can save you from a major breakdown and a lot of unnecessary stress. Don't wait for a complete failure like I did!

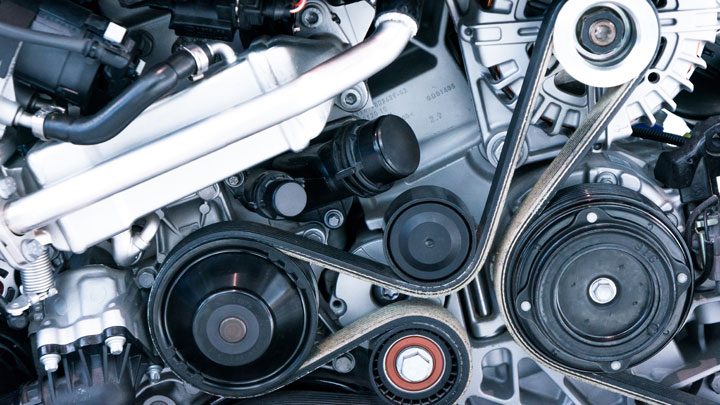

What Exactly Isa Serpentine Belt?

The serpentine belt, also known as an accessory drive belt, is a long, winding belt made of rubber or a composite material. Its job is to transfer power from the engine crankshaft to various engine accessories. These accessories typically include the alternator (which charges the battery), the power steering pump (which provides power assist for steering), the air conditioning compressor (which cools the cabin), and sometimes the water pump (which circulates coolant to prevent overheating). The belt wraps around pulleys attached to these accessories, and the crankshaft pulley drives the entire system. Think of it as the unsung hero under the hood, quietly orchestrating essential functions. When the serpentine belt fails, these accessories stop functioning correctly. A loose belt will slip and cause accessories to function intermittently or poorly. A broken belt will cause these accessories to stop working entirely, leading to potentially dangerous driving conditions. The serpentine belt is a critical component, and its health directly impacts the overall performance and reliability of your vehicle. Regular inspection and timely replacement are essential to prevent breakdowns and ensure a smooth and safe driving experience. Ignoring a worn or damaged serpentine belt is like ignoring a ticking time bomb – it's only a matter of time before it explodes into a major problem.

Serpentine Belt History and Myths

The serpentine belt, as we know it today, is a relatively modern invention. Before its widespread adoption, vehicles used multiple V-belts to drive individual accessories. Each accessory had its own belt, leading to a complex and often cumbersome system. The serpentine belt emerged as a more efficient and reliable alternative, simplifying the engine design and reducing the number of components. Its introduction marked a significant advancement in automotive engineering. One common myth surrounding serpentine belts is that they last forever. While modern belts are durable and long-lasting, they are still subject to wear and tear. Factors like heat, friction, and environmental conditions can degrade the belt over time, leading to cracks, fraying, and eventual failure. Regular inspection and replacement are crucial, regardless of what you might have heard. Another myth is that a squealing serpentine belt is harmless. While a slight squeal might seem insignificant, it's often a sign of a problem, such as a loose belt, worn pulleys, or misalignment. Ignoring the squeal can lead to further damage and a more costly repair down the road. Don't fall for these myths – treat your serpentine belt with the respect it deserves and you won't be sorry. Listen to your car; it’s trying to tell you something!

The Hidden Secrets of Serpentine Belts

Serpentine belts might seem like simple rubber bands, but they hide a few secrets. Did you know that the tension on the belt is crucial for its proper function? Too loose, and it slips, leading to poor accessory performance. Too tight, and it puts undue stress on the pulleys and bearings, shortening their lifespan. Maintaining the correct tension is an art, often requiring specialized tools and knowledge. Another secret lies in the belt's composition. Modern serpentine belts are made from advanced materials that offer superior strength, flexibility, and resistance to heat and wear. These materials are constantly evolving, with manufacturers striving to create belts that last longer and perform better. The seemingly insignificant grooves on the belt's surface also play a vital role. These grooves are designed to improve grip and reduce slippage, especially in wet or oily conditions. The design and depth of the grooves can vary depending on the vehicle and the application. The world of serpentine belts is surprisingly complex, with ongoing research and development aimed at improving their performance and reliability. Understanding these hidden secrets can help you appreciate the importance of choosing the right belt for your vehicle and maintaining it properly. Don’t underestimate the importance of these small details. The devil is in the details!

Serpentine Belt Recommendations: What to Look For

When it comes to serpentine belts, not all brands are created equal. Choosing a high-quality belt from a reputable manufacturer is essential for ensuring optimal performance and longevity. Look for belts made from durable materials with good heat resistance and tensile strength. Consider the manufacturer's warranty and reputation for reliability. A little research can go a long way in preventing future problems. It’s also crucial to choose the correct belt size and type for your specific vehicle. Consult your owner's manual or a qualified mechanic to ensure you get the right fit. Using the wrong belt can lead to slippage, premature wear, and damage to the accessories. Don't try to save a few bucks by buying a cheap, generic belt. Investing in a quality belt is a smart move that can save you money and headaches in the long run. Pay attention to the belt's construction and design. Look for features like reinforced cords and specially formulated rubber compounds that enhance durability and performance. Read online reviews and ask for recommendations from other car owners. Their experiences can provide valuable insights into the best serpentine belts on the market. Do your homework, and you'll be rewarded with a reliable and long-lasting serpentine belt that keeps your vehicle running smoothly. Don’t cheap out when it comes to parts of your vehicle; quality is key!

Decoding the Squeal: Identifying the Source

That ear-piercing squeal coming from under your hood is often the first sign of a serpentine belt issue, but it's not always the belt itself that's to blame. Sometimes, the squeal originates from a worn or misaligned pulley. The pulleys are the wheels that the serpentine belt wraps around, and if one of these pulleys is damaged or out of alignment, it can cause the belt to slip and squeal. Identifying the source of the squeal is crucial for proper diagnosis and repair. One way to pinpoint the culprit is to use a mechanic's stethoscope. This tool allows you to listen to individual components while the engine is running, helping you isolate the source of the noise. You can also try spraying a small amount of water on the serpentine belt while the engine is running. If the squeal disappears temporarily, it's likely that the belt is the problem. However, if the squeal persists, the problem is probably a pulley. Another potential cause of a squealing serpentine belt is a seized or failing accessory. If one of the accessories, such as the alternator or power steering pump, is not rotating freely, it can put excessive strain on the belt and cause it to squeal. In some cases, the squeal may only occur when the engine is cold, gradually disappearing as the engine warms up. This is often due to condensation or moisture on the belt or pulleys. The squeal can also be dependent on the weather as well. Determining the root cause of the squeal can save you from unnecessary repairs and ensure that you address the underlying issue.

Serpentine Belt Replacement: Tips and Tricks

Replacing a serpentine belt is a relatively straightforward task that many DIY mechanics can tackle. However, it's essential to follow the proper steps and take necessary precautions to avoid injury and ensure a successful repair. Before you begin, gather the necessary tools, including a wrench or socket set, a serpentine belt tool (if required), and a new serpentine belt that is the correct size and type for your vehicle. Disconnect the negative battery cable to prevent electrical shocks and accidental starting of the engine. Locate the serpentine belt tensioner, which is a spring-loaded pulley that maintains tension on the belt. Use a wrench or socket to release the tension on the tensioner, allowing you to remove the old belt. Carefully note the routing of the old belt around the pulleys before removing it. You can take a picture or draw a diagram to help you remember the correct path. Install the new belt, following the same routing as the old belt. Make sure the belt is properly seated in all of the pulleys. Use the tensioner to apply the correct tension to the belt. Refer to your owner's manual or a repair manual for the recommended tension specifications. Double-check that the belt is properly aligned and not twisted or kinked. Reconnect the negative battery cable and start the engine. Listen for any unusual noises or vibrations. After a few minutes, turn off the engine and inspect the belt to ensure it is still properly aligned and tensioned. Following these tips and tricks can help you replace your serpentine belt safely and effectively. If you're not comfortable performing this repair yourself, it's always best to consult a qualified mechanic.

Don't Ignore the Warning Signs

Ignoring the warning signs of a failing serpentine belt can lead to serious consequences. A broken serpentine belt can cause the alternator to stop charging the battery, leaving you stranded with a dead battery. It can also cause the power steering to fail, making it difficult to steer the vehicle, especially at low speeds. In some cases, a broken serpentine belt can also damage the water pump, leading to engine overheating and potential engine damage. These problems can be very costly, so it’s important to stay alert to the signs of a Bad or Loose Serpentine Belt. The squealing noise is hard to ignore, but you may also notice that your headlights are dimming. You might even get a warning light on your dashboard, such as a battery light or an overheating light. The sooner you address these problems, the less chance that they can lead to a dangerous or expensive issue. Regular inspection of the serpentine belt and paying attention to any unusual noises or symptoms can help you catch potential problems early. Replacing a worn or damaged serpentine belt is a relatively inexpensive repair compared to the potential damage that can result from ignoring the warning signs. Don't wait until it's too late – be proactive and protect your vehicle from a serpentine belt failure.

Fun Facts About Serpentine Belts

Did you know that the serpentine belt got its name because of its snake-like path through the engine compartment? It winds its way around multiple pulleys, resembling a serpent slithering through the engine bay. The length of a serpentine belt can vary depending on the vehicle and the number of accessories it drives. Some serpentine belts are only a few feet long, while others can be over ten feet long. Serpentine belts are made from a variety of materials, including rubber, neoprene, and EPDM (ethylene propylene diene monomer). EPDM belts are known for their excellent heat resistance and long lifespan. The tension on a serpentine belt is critical for its proper function. Too little tension can cause the belt to slip, while too much tension can damage the pulleys and bearings. Serpentine belts are constantly being improved with new materials and designs. Manufacturers are always looking for ways to make them more durable, efficient, and long-lasting. The lifespan of a serpentine belt can vary depending on driving conditions and maintenance practices. However, most serpentine belts are designed to last for at least 50,000 miles. Some high-quality serpentine belts can even last for over 100,000 miles. These seemingly simple components play a crucial role in the overall performance and reliability of your vehicle. Learning these fun facts will help you appreciate the importance of these under-appreciated parts.

How To Inspect Your Serpentine Belt

Inspecting your serpentine belt is a quick and easy way to identify potential problems before they lead to a breakdown. Begin by visually examining the belt for any signs of wear and tear. Look for cracks, fraying, glazing, or missing chunks of rubber. These are all indicators that the belt is nearing the end of its lifespan and needs to be replaced. Pay close attention to the grooves on the belt. If the grooves are worn or shallow, the belt may be slipping and not providing adequate power to the accessories. Check the belt tension. The belt should feel firm and not excessively loose. You can use a serpentine belt tension gauge to measure the tension accurately. If you notice any oil or other fluids on the belt, clean it off with a clean rag. Oil and other contaminants can degrade the belt material and shorten its lifespan. Inspect the pulleys for any signs of damage or misalignment. Make sure the pulleys are rotating smoothly and not wobbling. Listen for any unusual noises while the engine is running. A squealing noise is often a sign of a loose or worn serpentine belt. A ticking or clicking noise may indicate a damaged pulley or bearing. Make sure to do these inspections regularly, for example when you change your oil. Regular inspection of your serpentine belt can help you identify potential problems early and prevent a costly breakdown. If you're not comfortable performing this inspection yourself, you can always take your vehicle to a qualified mechanic.

What If You Ignore a Bad Serpentine Belt?

Ignoring a bad serpentine belt can have serious consequences for your vehicle. The serpentine belt drives many essential components, including the alternator, power steering pump, air conditioning compressor, and water pump. If the belt breaks, these components will stop working, which can lead to a variety of problems. A broken serpentine belt can cause the alternator to stop charging the battery, which can leave you stranded with a dead battery. It can also cause the power steering to fail, making it difficult to steer the vehicle, especially at low speeds. In some cases, a broken serpentine belt can also damage the water pump, leading to engine overheating and potential engine damage. These problems can be dangerous and can also be very costly to repair. A broken serpentine belt can also cause other components to fail, such as the idler pulley. The idler pulley is a small pulley that helps to guide the serpentine belt around the engine. If the serpentine belt breaks, it can put excessive strain on the idler pulley, causing it to fail. It can also cause the air conditioning compressor to fail, which will leave you without cold air in the summer. In general, the issues related to a Bad or Loose Serpentine Belt can be very expensive if you ignore them. In order to prevent this, make sure to stay up to date on maintenance!

Listicle: 5 Reasons to Replace Your Serpentine Belt ASAP

Here are five compelling reasons why you should replace your serpentine belt as soon as you notice any signs of wear or damage:

1.Prevent breakdowns: A worn or broken serpentine belt can leave you stranded on the side of the road, which is never a fun experience. Replacing the belt before it fails can prevent this from happening.

2.Maintain essential functions: The serpentine belt drives essential components such as the alternator, power steering pump, and air conditioning compressor. Replacing the belt ensures that these components continue to function properly.

3.Avoid costly repairs: Ignoring a bad serpentine belt can lead to damage to other components, such as the water pump or idler pulley. Replacing the belt can prevent these costly repairs.

4.Improve fuel economy: A worn serpentine belt can cause the engine to work harder, which can reduce fuel economy. Replacing the belt can improve fuel economy and save you money on gas.

5.Ensure safety: A broken serpentine belt can cause the power steering to fail, making it difficult to steer the vehicle. Replacing the belt ensures that you have full control of your vehicle.

Don’t ignore these signs; they are trying to help you. Make sure that you stay up-to-date with the maintenance of your vehicle!

Question and Answer: Serpentine Belt Edition

Q: How often should I replace my serpentine belt?

A: The recommended replacement interval varies depending on the vehicle and the type of belt. Consult your owner's manual or a qualified mechanic for specific recommendations. However, a good rule of thumb is to replace the serpentine belt every 60,000 to 100,000 miles, or every 5 to 7 years, whichever comes first.

Q: Can I drive with a squealing serpentine belt?

A: It's generally not recommended to drive with a squealing serpentine belt. The squeal indicates that the belt is slipping, which means it's not providing adequate power to the accessories. This can lead to a variety of problems, such as a dead battery or power steering failure.

Q: How much does it cost to replace a serpentine belt?

A: The cost of replacing a serpentine belt can vary depending on the vehicle and the labor rate. However, you can expect to pay anywhere from $100 to $200 for the parts and labor. Some can be even more expensive, depending on what type of car that you own.

Q: Can I replace a serpentine belt myself?

A: Replacing a serpentine belt is a relatively straightforward task that many DIY mechanics can tackle. However, it's essential to follow the proper steps and take necessary precautions to avoid injury and ensure a successful repair. If you're not comfortable performing this repair yourself, it's always best to consult a qualified mechanic.

Conclusion of Bad or Loose Serpentine Belt: Symptoms and Replacement

The serpentine belt, a seemingly simple component, plays a crucial role in your vehicle's overall health and performance. Recognizing the symptoms of a failing belt, understanding its function, and knowing when and how to replace it are essential for preventative maintenance. By being proactive and addressing potential issues early, you can avoid costly repairs, prevent breakdowns, and ensure a safe and reliable driving experience. Regular inspections, quality replacement parts, and a bit of knowledge can go a long way in keeping your serpentine belt – and your vehicle – running smoothly for years to come. Don't underestimate the power of a healthy serpentine belt!